LV Detuning Reactors

Application

Frequent use of power electronic devices with nonlinear

loads leads to harmonic distortion in electrical system.

This nonsinusoidal load causes increase of effective

current of power capacitor and other components of the

system as well as the posibility of capacitor resonance

with other inductive loads. Finally it may lead to problems

or even failures in the installation. The solution is to

use detuning {filtering) reactors, which creates a series

resonant circuit with power capacitors. This detuned

system prevents the installation from resonance effect and

also acts as a filter for higher harmonic content. Usually

there is recommended to use detuning reactors for the

total voltage distortion THD-U higher than 3 %.

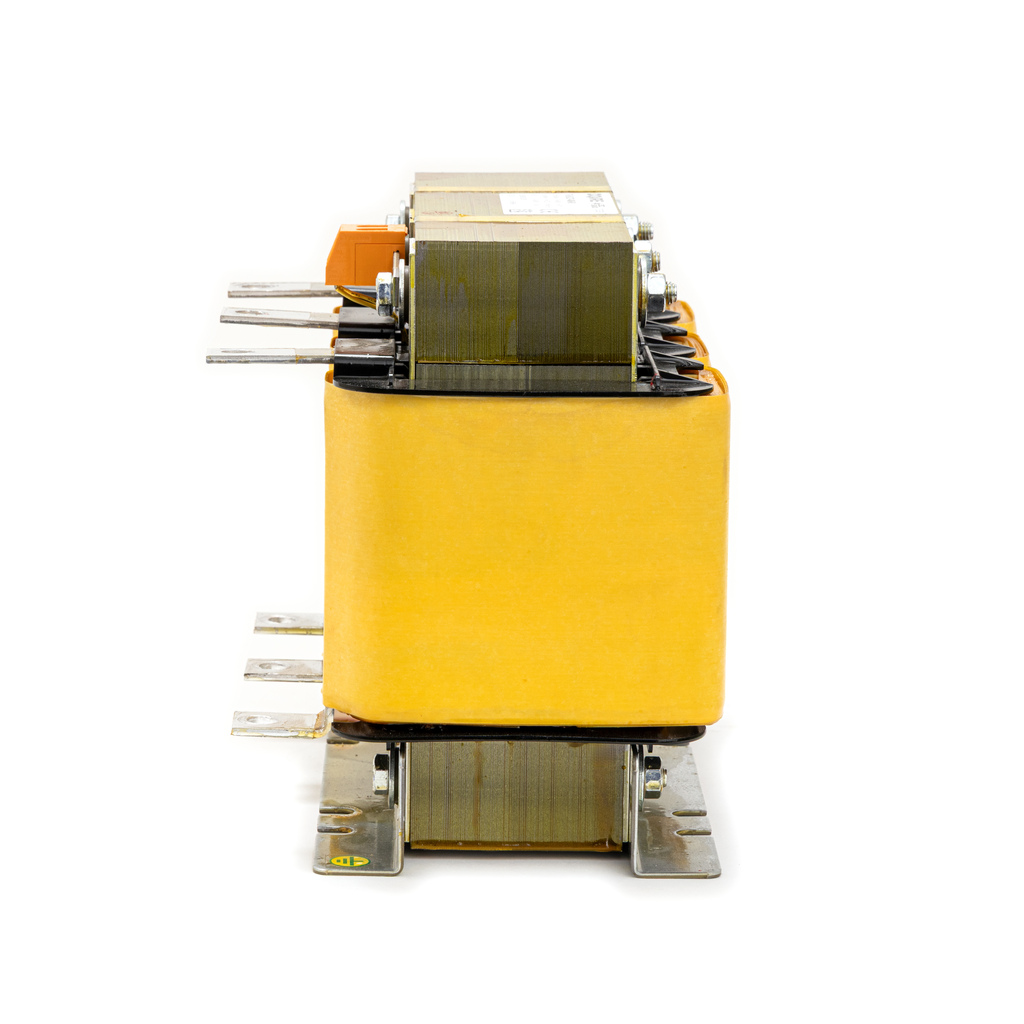

Construction

Detuning reactors are produced from high grade, low

loss transformer sheets, with winding either from copper

wire or aluminium band. Iron core is designed with multi

air gap to meet high current linearity and low thermal

losses. They are impregnated with high quality epoxy

resin to ensure good insulation, low noise and long

lifetime. Reactors are equipped with thermal protection to

prevent overheating. Reactors with lower rated power are

designed with copper wire and outlets via terminal block or

cable lug. Higher power rated reactors are produced from

aluminium band with outlets as aluminium bars (copper

outlets are possible on request).

More Details

| Standards | IEC EN 60076-6, IEC EN 61558-2-20 |

|---|---|

| Rated Voltage | 400 / 60 Hz |

| Rated Power | 25-50kVAr (other ratings upon request) |

| Inductance Tolerance | -5 / +5 % |

| Detuning Factor | 7 % |

| Resonance Frequency | 227 Hz (Other ratings upon request) |

| Temperature Class | F (155 °C) |

| Ambient Temperature | 40 °C |

| Statistical Life Expectancy | > 200 000 hours |

| Protection Degree | IP 00 |

| Insulation (winding – core) | 3 kV |

| Max. Relative Humidity | 95 % |

| Max. Altitude | 4 000 m |

| Cooling | Natural Air or Forced |

| Design | Three phase, iron core with multi air gap |

| Winding Material | Copper (TKC), Aluminium (TKA) |

| Impregnant | Polyester (epoxy) resin |

| Safety Device | Thermal switch (TKA-130 °C, TKC-90 °C) |

| Terminals | Terminal block, Al bar |

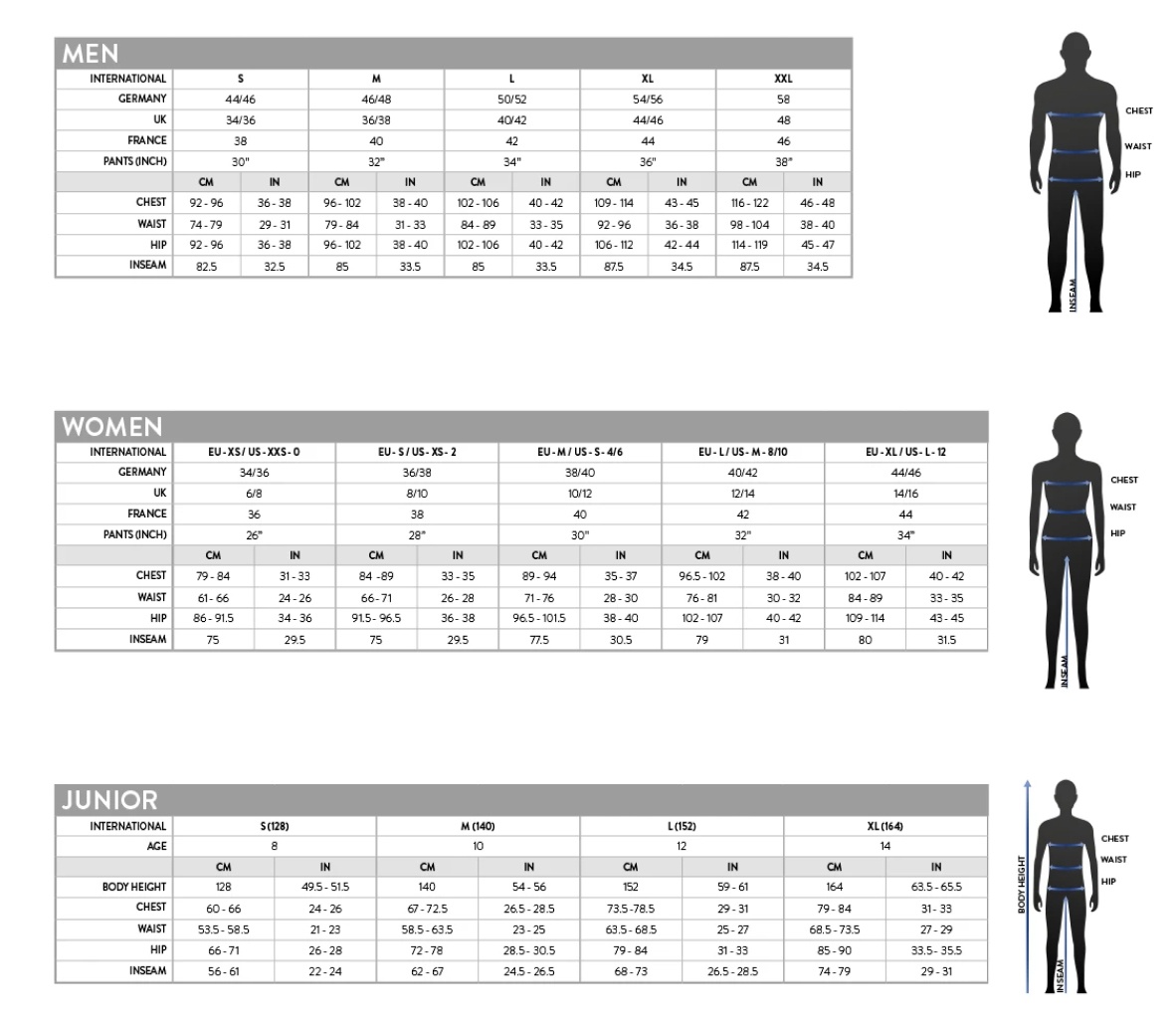

| Qc (kvar) | Cɴ (Δ) (µF) | Type | Capacitor Model | Quantity | Lɴ (mH) | Iɴ (A) | m (kg) | Losses (W) | WxDxH (mm) | Design |

|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 3 x 128 | TK-25-227-400-60 | CSADG-0,48/33,3-60-HD | 1 | 1,28 | 36,0 | 13 | 120 | 240 x 160 x 160 | 2 |

| 50 | 3 x 257 | TK-50-227-400-60 | CSADG-0,48/33,3-60-HD | 2 | 0,64 | 72,2 | 23 | 144 | 255 x 185 x 215 | 2 |